Enhanced Productivity

Most other forms of storage, including on-site storage and customer storage, can’t compare to the efficiency of a well-run warehouse. This is because warehouses are constructed with the sole purpose of housing and transporting commodities. They are also often situated near major transit nodes, which reduces travel time and boosts productivity.

Conveyor belts and forklifts are two examples of specialized machinery used in warehouses to facilitate the rapid and efficient transfer of items. Furthermore, warehouses are overseen by seasoned personnel who have received extensive training in the most efficient methods of warehousing and transportation.

Less Danger

Storage may lessen supply chain uncertainty. Warehouses are ideal for keeping products and spare stock since they are secure and out of the way. In addition, they include high-tech security systems that deter break-ins and safeguard valuables. Insurance on warehouses also shields firms from financial damage in the case of a fire, flood, or other catastrophe.

Reduced Expenses

Saving money is a major benefit of employing third-party logistics. For instance, a tiny online store selling handmade goods could not afford a warehouse and all the necessary equipment and staff. To save expenses and concentrate on its core strengths of production and promotion, the company has decided to outsource its warehouse operations to a third-party logistics (3PL) supplier.

Knowledge and Cutting-Edge Tools

Expertise and cutting-edge equipment are another advantage of contracting out for storage space management. Another benefit is that the service provider’s insurance and legal protections might let smaller businesses take less risk. Even if they are very tiny, manufacturers of medical devices are subject to rules and quality standards set by organizations like the FDA and ISO. The producer may avoid the expense and hassle of developing in-house expertise and infrastructure dedicated to healthcare logistics by contracting with a 3PL provider specializing in medical items’ storage and distribution.

Functions That Warehouses Provide

Assurance of Quality

Quality control in storage facilities effectively ensures goods meet company specifications, which is crucial for any business. Companies may protect their image and customers’ happiness by implementing inspection and testing procedures and maintaining a high level of supply chain monitoring. Companies may reduce their vulnerability to product failure by using tried and true quality management practices.

Controlling Stocks

Inventory management includes monitoring stock, restocking when necessary, and anticipating sales. Warehouse management software keeps track of stock levels in real-time and alerts employees when supplies are running short; an ABC analysis helps firms determine which goods consumers value most. Radiofrequency identification (RFID) tags make quick scanning upon warehouse arrivals possible.

All of these instruments contribute to improved resource management, which in turn expedites the fulfillment of orders. Optimizing business operations using a Warehouse Management System or WMS is highly suggested for greater efficiency, as it speeds up order fulfillment by supplying appropriate amounts at any given moment.

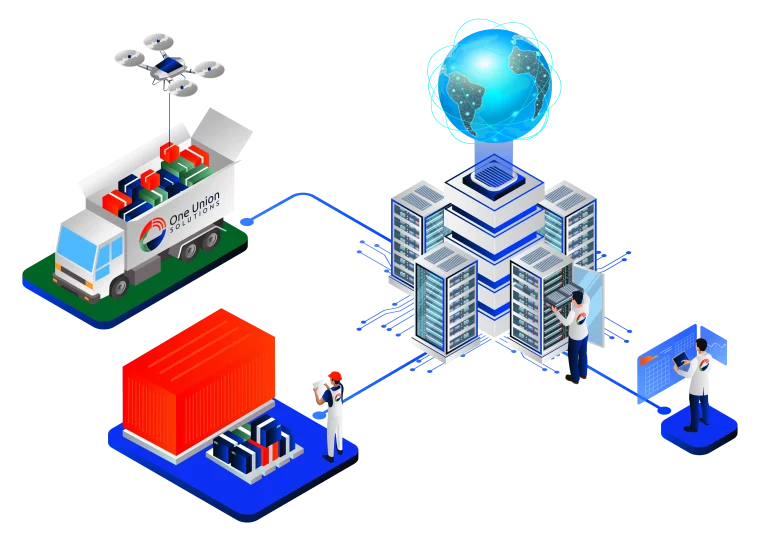

Why You Should Trust Us

Just like the logistics industry, we are always evolving and improving. One Union Solutions can safely guarantee the highest possible standard method for managing any Customs procedures because of our one-of-a-kind approach, exceptional service, and creative solutions. Initially, they zeroed solely on providing solutions for the publishing sector.

We provide customized attention and assistance to each of our clients. Our primary service is on-site inspections, round-the-clock phone, and digital aid. Our extensive stock can help you with your warehouse or manufacturing needs. You may purchase only one of our products or build elaborate systems with various components.