Benefits of Warehousing Logistics

Warehousing is often seen as a place to temporarily store goods until they are shipped or picked up at their ultimate destination. However, this service is crucial for a functioning logistics system as it clarifies the advantages of storage, which freight forwarders and their clients appreciate.

Warehousing’s Positive Effect on the Economy

Central warehouses make Consolidation processes possible by eliminating the need for individual shipments. Customers may split the cost of shipping their orders out of the warehouse with others whose packages are headed in the same direction. The ability to accumulate is another economic advantage of storage. Warehousing services offer the ideal conditions for storing a product all year, making them suitable for delivering a seasonal item with consistent demand.

Safety

Customers with strict delivery schedules may ensure their items arrive on time if they maintain a buffer supply. In the event of an unexpected delay in their next cargo, the firm handling your freight can still get it to you on time because of the emergency stockpile it has on hand.

Products’ Upkeep And Repair

One Union Solutions warehouses have a staff of seasoned workers who oversee everything from when cargo arrives until it is sent. Save money by keeping real-time tabs on inventory and the cost of goods sold (COGS). Warehouse management software makes it easier to spot ineffective procedures. You may use this information to make smarter choices about distributing your resources among projects.

Boost productivity: Boost productivity both inside and across sections of a company or different places. Employees with specialized skill sets or knowledge bases can now complete tasks more quickly than ever, thanks to access to real-time data. In contrast, employees who may not have these skill sets can still access those same resources by utilizing their own skill sets.

Top Features Of Warehouse Management System

The goal of warehouse management systems (WMS) is to optimize warehouse operations and processes. With a WMS, you can guarantee your goods’ quickest and least expensive distribution. It’s a tool for keeping tabs on your warehouse’s layout, stock, picking, packing, shipping, receiving, employees, and reports.

Receiving

To get things rolling, a WMS has to have a way to take delivery of packages. This function of WMS keeps track of differences between the purchase order and the actual items received, reducing the likelihood of receiving mistakes. The ERP system communicates in real-time with the warehouse app so that you can always monitor stock levels. WMS will provide several slotting and storage space optimization strategies based on the nature and features of the products you manage.

Fast-moving products, for instance, should be put where they will see the most significant foot traffic. At the same time, delicate IT, medical hardware, automotive, and aviation goods should be kept in locations where they will be protected from damage, and perishables should be filed away according to their specific needs and the date they would go wrong.

Managing Stocks

The dashboard of a WMS platform is constantly updated with the most recent data as it is gathered via barcode scanners and RFID tags, allowing authorized users access to the most accurate and up-to-date records of inventory levels. It also helps make sure things are easy to find and transport. Warehouse management systems oversee operations, including kitting, cycle counting, cross-docking, and more. An efficient WMS will suggest IT, medical hardware, automotive, and aviation goods to count and their locations, and make ERP system adjustments to make cycle counting easier.

Taking Orders

A vital function of any warehouse management system is streamlining the procedures involved in taking orders and fulfilling them. By controlling the movement of IT, medical hardware, automotive, and aviation goods through the warehouse, a WMS may help you better manage orders. Connectivity to carrier networks is a feature of specific WMS that may greatly benefit logistics processes. In Addition, as automation integration spreads, warehouse managers will save time on tasks like entering data manually.

Employing robots, AI, and ML to automate warehouse management systems may significantly improve productivity and speed. Using picking robots, warehouses can find and distribute things without sending employees back and forth. Conveyor systems allow for the hands-free movement of goods throughout the warehouse and out for shipment.

Labor Administration

Tools for managing employees are another WMS function, alongside the many unique features that allow for identifying and tracking actual items and deliveries. Effective labor management may keep workers focused and reveal procedures that waste time and money.

Some of the finest warehouse management software available today allows for the incorporation of complex labor management modules, which organizations use as part of corporate automation solutions. A labor management system may create a database of workers, organize their shifts, and assign each worker to a particular position. Labor is crucial to achieving the desired results in any endeavor.

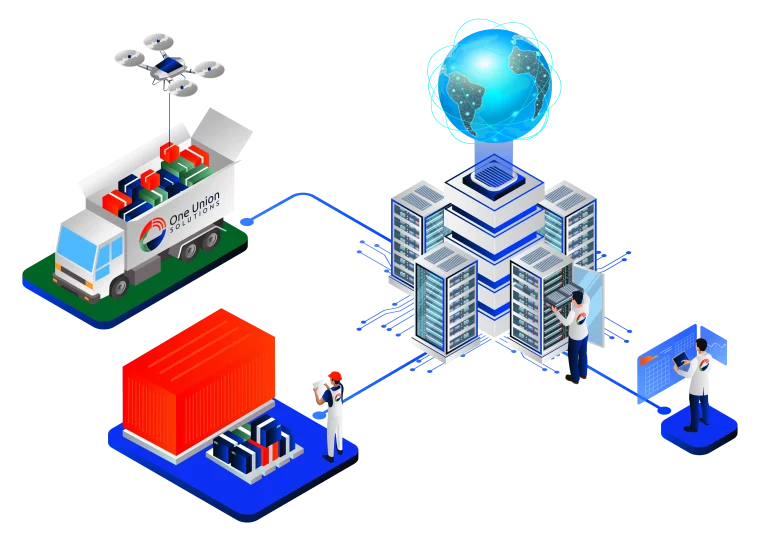

Why One Union Solutions

Just like the logistics business, we are constantly improving and developing. One Union Solutions‘ tailored strategy, excellent service, and innovative solutions provide the highest possible standard for handling any Customs activities. Initial efforts focused on publishing industry solutions. Our goods and services may now be modified to suit the requirements of each given warehouse or distribution center.

We value maintaining consistent communication with our clients. Each of our customers receives tailored service and support from us. Our core service includes on-site inspections and 24/7 availability through phone and online chat.