Advantages of Utilizing IOR Services in Oregon

- The benefits of IOR services are maximized throughout the operating period. These services aim to simplify regular operations, enhance routines, and boost efficiency. Businesses in Oregon may improve their market competitiveness by engaging qualified specialists to monitor and manage industrial processes to reduce downtime, pinpoint sources of inefficiency, and execute effective fixes.

- Oregon industrial establishments benefit from the maintenance included in IOR services in the end. Machines and tools only last as long as the maintenance is performed. This provides a cost-effective asset management method by decreasing the chance of unexpected failures and increasing the lifetime of assets. The consequence is more excellent dependability and a higher return on investment for industrial firms.

- Employment opportunities and talent pool development are two other ways the economy benefits from IOR services. The industrial sector in Oregon benefits from increased competitiveness thanks to the employment of skilled workers in installation, operation, and maintenance.

- Additionally, Oregon’s dedication to environmental sustainability is in line with the adoption of IOR services. These services are environmentally responsible since they emphasize saving resources and minimizing waste. Businesses in Oregon may improve their corporate social responsibility and boost the state’s image as a leader in environmental protection by adopting sustainable practices and complying with environmental rules.

Future of Oregon’s IOR Industry

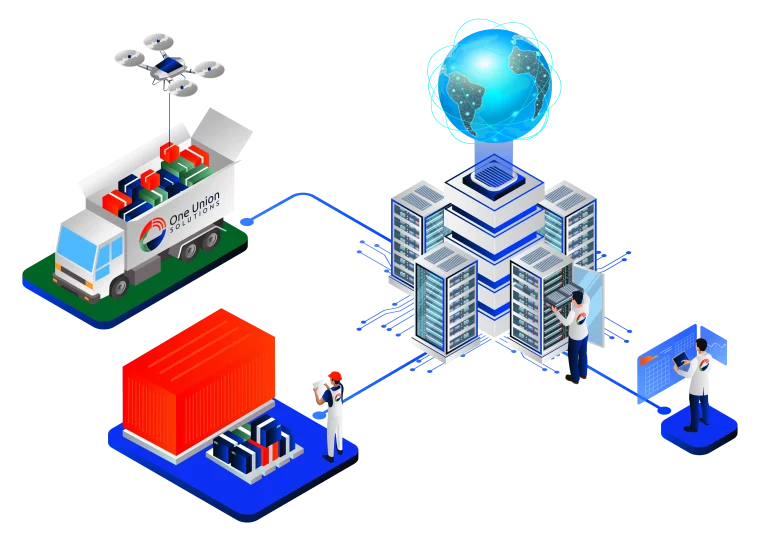

Oregon’s future in installation, operation, and maintenance (IOR) services will be significantly influenced by new technologies, environmental needs, and an increasing focus on efficiency and creativity within the industry. The reliance on innovative technology will be a defining characteristic of IOR services, with automated systems making equipment installation easier and faster. Artificial Intelligence (AI) will play a crucial role by analyzing large volumes of data in real time, enhancing operational efficiency, and predicting maintenance needs to reduce downtime. Additionally, the Internet of Things (IoT) will facilitate connected manufacturing environments, allowing for improved monitoring and management of operations.

Sustainability will also be a major factor in the evolution of IOR services. As the government intensifies its commitment to environmental protection, there will be a strong push for the adoption of renewable energy and eco-friendly practices in manufacturing. IOR services will focus on optimizing energy use, lowering carbon footprints, and embracing circular economy principles that emphasize material reuse.

Training programs for IOR specialists will undergo significant changes due to these technological advancements. Tools like Augmented Reality (AR) and Virtual Reality (VR) will be utilized to provide real-time information and virtual assistance during maintenance, leading to faster and more accurate repairs. The workforce in IOR services will evolve as well, with a greater demand for skilled workers proficient in digital technology and media. Consequently, training programs will need to adapt to equip workers for the challenges posed by automated and interconnected industrial systems.

Furthermore, the development of IOR services in Oregon will be shaped by state regulations. As environmental laws become stricter, companies will be required to adopt responsible practices and ensure compliance with safety and sustainability standards in all their operations. In summary, Oregon’s IOR services are poised to become more efficient, sustainable, and technology-driven, necessitating a skilled workforce and adherence to evolving regulations.