Features of Warehousing Services in the USA

Keeping a warehouse in good order and functioning efficiently is often more complex than people credit it for being. It’s easy to assume that a warehouse’s only purpose is to hold goods until they can be sent overseas or sold locally. Still, a sound warehouse management system also has many other functions.

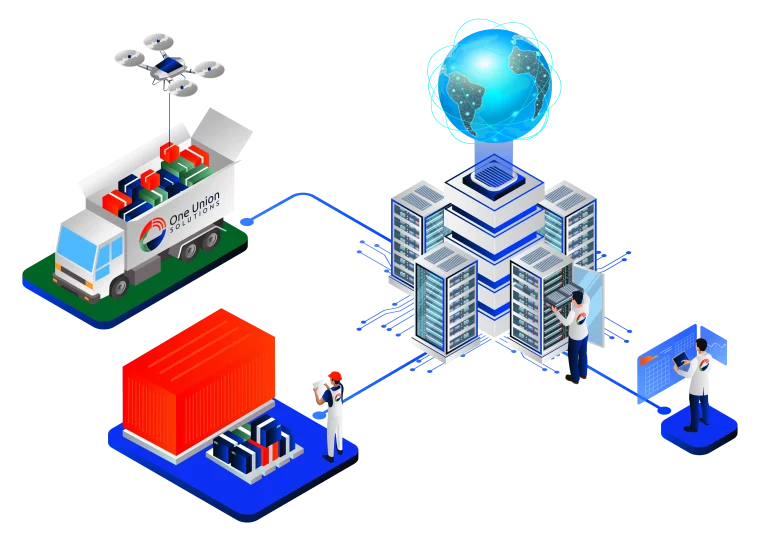

Warehousing is storing items and cargo using scientific procedures so that they may be quickly and easily accessed whenever transport requires. The success of any business in today’s consumer market hinges on the efficiency and effectiveness of its warehouse operations.

Proximity to a Market

Locate your warehouse in a readily accessible and well-connected region. Loading and unloading your items will proceed more smoothly if convenient means of transportation and communication are in place, such as roads, railroads, airfields, and ports. Your employees will appreciate the convenience, and the warehouse’s productivity will increase.

Parking Areas and Surrounding Areas

No matter where you put your warehouse, enough parking space must surround the structure. This is essential for speedy product loading and unloading.

Machines and Tools

The proper equipment is vital to the efficient operation of any warehouse. This reduces expenses and makes it easier to manage heavy or cumbersome goods. The racking system in your warehouse will need to be specially constructed to accommodate the storage of huge and heavy objects. To prevent spoilage, cold food storage facilities must give top priority to their refrigeration systems.

Ensure your warehouse is suitable for storing the merchandise you want to keep. Protocol in Disaster Your warehouse has to always be ready in case of an accident or other Disaster. Prepare for any emergency, whether fire, flood, mechanical catastrophe or anything else.

Organization

You must be organized if you want inbound merchandise to get to the right areas and your pickers to quickly locate the products they need. Get your supplies in the order that makes the most sense for your procedure and set up a mechanism to track that order.

Do not arrange for the sake of organization; instead, think about the logical placement of the different items. Products often purchased together should be shelved next to one another, prominently high-turnover goods should be displayed, etc.

Benefits of Logistics Warehouse

To ensure that your IT equipment is always stored in a safe and secure environment, our warehouses have cutting-edge temperature control and security technologies. One Union Solutions facilities provide the optimal setting for protecting the integrity of your technological assets, whether you need to keep servers, networking gear, or high-tech devices.

In the aviation industry, accuracy and dependability are critical. Aircraft components, avionics gear, and maintenance instruments all have their specific storage options that we provide. We keep aircraft parts in perfect condition in our hangar-like facilities, which are easily accessible for maintenance or rapid deployment, thanks to our specialized racking and storage systems.

Effective inventory management is a must in the automotive business. Our warehouses have been thoughtfully designed to store various automobile components. Store everything from engines to tires and anything in between with ease thanks to our flexible, modular storage solutions.

The safekeeping of delicate equipment is a matter of life and death in the medical industry. To ensure the safety of medical devices and equipment, our facilities adhere to strict quality requirements, such as climate control.One Union Solutions warehouse services are equipped to handle medical equipment with the highest care and security since we know how important it is.

Why Should You Choose Us

We, like the logistics business, are constantly developing and changing. Because of our unique approach, excellent service, and innovative solutions, One Union Solutions can confidently guarantee the finest standard technique for handling any Customs procedures. At first, they focused on finding answers for the publishing industry. Our goods and services may now be modified to fit the specifications of any given warehouse or distribution centre.

Support and Facilitation

We value maintaining consistent communication with our clientele. Each of our customers receives tailored service and support from us. Our core service includes on-site inspections and 24/7/365 phone and electronic support. Warehouse and production assistance may be found in our comprehensive inventory. You may buy a single one of our products or combine many products into more complex setups.