The Importance of Storage for Successful Logistics

Sweden’s transportation, industrial, and import/export sectors all rely extensively on warehousing. Despite the fact that it could seem like a one-time expense, it actually leads to long-term savings and improved operational effectiveness. The capacity of warehouses to efficiently manage inventory and swiftly complete orders leads to increased revenue.

Important Warehouse Characteristics

Modern warehouses in Sweden include a range of amenities to improve logistical operations:

1. Climate-controlled spaces for products sensitive to temperature.

2. Sophisticated security measures, such as cameras, alarms, and 24-hour guards.

3. Plans that can be customized to meet different storage demands.

4. Extra value-added services include kitting, assembling, labeling, quality control checks, and repackaging.

Facilities for Specialized Warehousing are Available

1. Private Warehouses: These facilities are owned and managed by businesses and used for order fulfillment, distribution, and warehousing.

2. Public Warehouses: Open to the public and providing space for rent.

3. Bonded Warehouses: Safe holding facilities for imported commodities while they wait to be cleared by customs.

4. Distribution Warehouses: Consolidated supply chain nodes for bulk products.

5. Order fulfillment centers: Providing for the needs of processing consumer orders for online businesses.

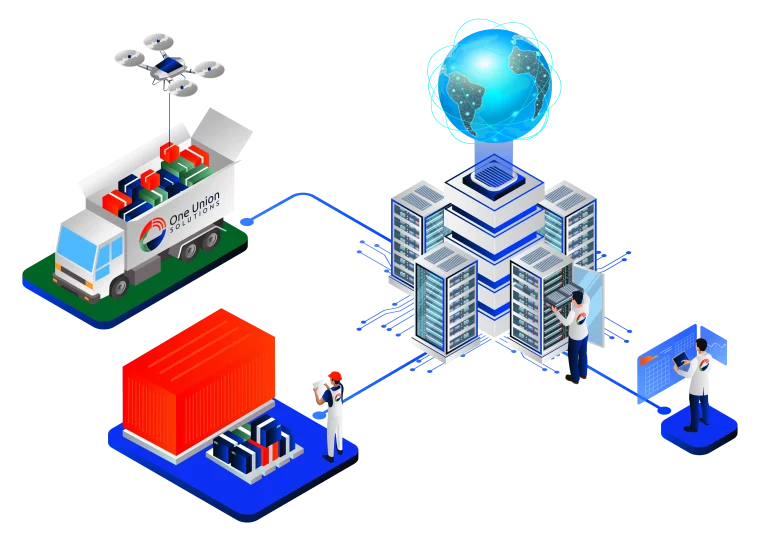

What Makes One Union Solutions the Best?

With its distinctive approach, first-rate service, and cutting-edge solutions, One Union Solutions is at the forefront of the logistics sector’s ongoing evolution. We can meet all of your needs, including on-site inspections, 24-hour electronic support, and a wide selection of production and warehouse equipment. Our experience guarantees efficient logistics management and easy-going customs procedures.

Experience in Cold Chain Logistics

The cold chain logistics capabilities of Sweden are well advanced. Pharmaceutical, culinary, and biotechnology businesses all benefit from temperature-controlled warehouse facilities. For sensitive products like vaccines, perishable foods, and biopharmaceuticals to remain intact, these facilities maintain precise temperature and humidity levels.

Modernized Inventory Management Methodologies

Modern inventory control systems are used in Swedish warehouses. These systems make use of RFID (Radio-Frequency Identification), barcoding, and IoT (Internet of Things) sensors to provide real-time visibility into inventory levels, assisting customers in making educated decisions about stock replenishment and order fulfillment.

Initiatives for environmental sustainability

Sweden prioritizes sustainability as a fundamental value. Storage companies frequently use environmentally friendly techniques including solar energy generation, rainwater collection, and energy-efficient lighting. Additionally, they could take part in sustainability certification programs to demonstrate their dedication to lowering their environmental impact.

E-commerce fulfillment facilities

E-commerce fulfillment centers have gained popularity in Sweden as a result of the expansion of online purchasing. These facilities focus on processing and delivering orders for online retailers, guaranteeing prompt and correct delivery to clients and enabling firms to increase their online presence.

Personalized Storage Options

Swedish warehouse operators are aware that there is no one-size-fits-all solution. To meet the demands of various products, they provide customized storage solutions. This comprises special handling for things that require particular handling, hazardous materials, and specialist storage for big objects.

Positioned for Nordic and Baltic markets

Sweden is the perfect choice for warehousing and distribution because of its strategic location at the crossroads of the Nordic and Baltic regions. Sweden’s warehouses provide entry points into not only the Swedish market but also those of its neighbors, giving companies quick access to a large clientele.

Services for facilitating trade

Providers of warehousing frequently provide complete trade facilitation services. This includes support with trade compliance, import/export laws, and customs documentation. They assist companies in navigating the difficulties of global trade, ensuring that commodities move freely across borders.

Liquid and Bulk Storage

Swedish warehouses provide specialized storage options for liquids and large commodities. This covers both bulk storage for goods like grains, minerals, and chemicals as well as locations set up for the storage of liquid goods like oils, chemicals, and beverages.

Expertise in Cross-Border Trade

Swedish warehouses provide significant knowledge of customs procedures, taxation, and trade rules unique to these regions for enterprises engaged in cross-border trade with Norway, Finland, Denmark, and other bordering countries.

Certifications and Quality Control

Many warehousing companies in Sweden follow industry certifications like ISO 9001 (Quality Management System) and ISO 14001 (Environmental Management System) to maintain high standards. These certificates attest to their dedication to excellence and environmental stewardship.

Effective Order Picking and Filling

Sweden has automated storage and retrieval systems (AS/RS) and voice-directed picking technologies installed in its warehouses, which are both state-of-the-art order-picking systems. These programs promote operational efficiency overall, improve order fulfillment, and decrease picking errors.

Supply Chain Consulting

Some warehouse companies also offer supply chain consultancy services in addition to storage and delivery. They work together with clients to increase the efficiency of their supply chains, find ways to cut costs, and put best practices into action.

Transport Services with Temperature Control

Some Swedish warehouse operators now provide temperature-controlled transportation services as an addition to their cold storage capabilities. This guarantees that goods that require controlled temperatures are delivered to their destinations without sacrificing quality.

Cooperative Relationships

With airlines, technology companies, and logistics service providers, warehousing providers frequently form cooperative agreements. Through these partnerships, they are able to provide complete supply chain solutions, including last-mile delivery, transportation, and tech-based options.

Compliance with food safety standards

Compliance with food safety standards and laws is crucial for warehousing operations that handle food goods. To guarantee that food products are handled and kept in compliance with legal standards, warehouses in Sweden adhere to strict cleanliness and safety protocols.

Pharmaceutical Regulatory Compliance

Good Distribution Practice (GDP) observance is crucial in the pharmaceutical industry. Pharmaceutical-specific warehouse companies adhere to GDP regulations, guaranteeing the secure storage and distribution of medical supplies.

Emergency Preparedness and Disaster Recovery

Swedish warehouses are well-equipped to handle catastrophes and natural disasters. To protect stock, equipment, and staff in the event of unforeseen disasters, they create thorough emergency response and disaster recovery plans.

Management of Reverse Logistics

Swedish warehouses actively handle reverse logistics, which includes managing returns, recycling, and product disposal. They help companies process returned goods, reduce waste, and effectively manage the reverse flow of commodities.

Analytics and Customized Reporting

Warehouse service providers provide specialized reporting and analytics capabilities to aid with data-driven decision-making. Customers get access to in-depth information on key performance indicators (KPIs) such as order accuracy, inventory turnover, and storage costs.

Reliable Dock Operations

To speed up the loading and unloading of cargo, Swedish warehouses enhance their dock operations. Truck turnaround times can be shortened by using dock levelers, loading bays, and effective scheduling.

Collaborative robots (Cobots)

Collaborative robots or cobots, are used by several warehouse service companies. By helping with operations like palletizing, inventory counting, and order picking, these robots support human workers and increase productivity.

Risk assessment and security audits

For the purpose of locating weaknesses and potential security threats, warehouses conduct routine security audits and risk assessments. This proactive strategy ensures the protection of goods and workers and helps prevent security breaches.

Slot optimization and inventory sizing

To make sure that products are housed in the most practical and accessible areas within the warehouse, warehouse providers use inventory slotting and optimization procedures. This decreases picking time and accelerates order fulfillment.

Supplier Cooperation Initiatives

To increase the effectiveness of the supply chain, warehousing companies frequently work with suppliers. Data, demand projections, and inventory information are shared as part of supplier collaboration initiatives to balance supply and demand.

Solutions for Multi-Tier Warehousing

Multi-tier warehousing solutions are offered for companies with various storage requirements. These facilities have many floors of storage, enhancing storage capacity and effectively utilizing vertical space.

Platforms for Real-Time Visibility

Many storage suppliers offer real-time visibility technologies to improve supply chain transparency. Customers can access real-time data on inventory levels, order status, and shipment tracking via these systems.

Reduction of Waste Initiatives

Initiatives to reduce waste are included in sustainability efforts. Swedish warehouses adopt recycling and waste management plans to reduce their operations’ negative environmental effects.

Strategies for Inventory Segmentation

Inventory segmentation techniques are used in warehouses to group products according to demand, seasonality, and shelf life. This makes storage and order fulfillment more effective.

Warehouses Bonded by Customs

Some service providers also run customs-bonded warehouses in addition to their standard warehousing operations. Customs authorities have granted these facilities permission to hold imported goods under bond while deferring payment of customs charges until the commodities are released.