The Role of Technology in Modern Warehousing for Business Growth

Technology has significantly enhanced the warehousing industry in Peru, leading to more efficient and accurate processes. Advanced inventory management systems and automated picking and packing methods have transformed traditional storage facilities into modern logistics hubs, driving industry growth. Warehouse management systems (WMS) are revolutionizing contemporary warehousing by enabling real-time tracking of inventory, optimizing storage space, and facilitating order fulfillment processes. WMS provides accurate data for industries to make informed decisions, reduce costs, and enhance customer satisfaction.

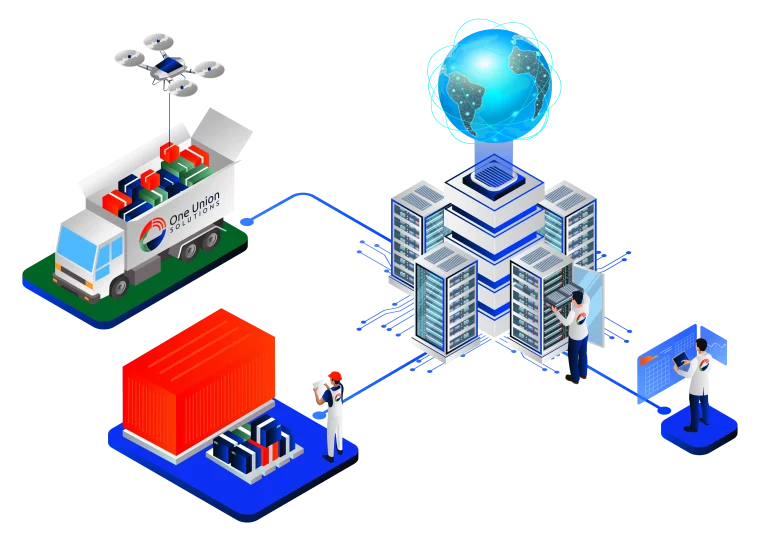

Warehouse operations are integrating technologies such as AI, robotics, and IoT. Robots handle repetitive tasks, while AI tools enhance efficiency through analytics. IoT devices monitor inventory in real-time for convenient replenishment. Embracing these innovations is essential for companies to remain competitive in the warehousing sector.

Challenges and Solutions in the Warehousing Sector of Peru

The warehousing industry in Peru presents both opportunities and challenges. A major challenge is compliance with trade laws and obtaining essential certifications, such as the Trade Compliance Certificate. This certification ensures that industries meet legal and security requirements. Navigating these laws can be daunting, but partnering with experienced agencies simplifies the process and ensures compliance. One Union Solutions can provide such compliance for smooth operations. Warehouses in Peru face the challenge of effectively managing inventory. To maintain optimal levels, it is crucial to monitor inventory levels, prevent shortages, and minimize excess stock.

Implementing inventory management strategies and a Quality Assurance Team can help address these challenges. Regular audits, monitoring expiration dates, and optimizing storage spaces are crucial techniques for ensuring convenient order fulfillment and reducing waste.

Warehousing Strategies for Streamlining Operations and Increasing Productivity

Warehouses in Peru can improve processes and productivity by implementing techniques such as automated picking technologies, barcode scanning, and optimized picking paths. These measures aid in reducing errors, improving order accuracy, and enhancing overall efficiency.

One way to enhance warehouse efficiency is by reconfiguring the layout, optimizing storage space, and using efficient material handling equipment. This helps minimize travel distances and maximize space utilization, leading to reduced costs and improved processes.

Utilizing data analytics and real-time tracking technologies can provide warehouses with valuable insights into their operations. Analyzing peak periods, order volumes, and product demand allows warehouses to make informed decisions about resource allocation, staffing, and inventory management. This data-driven approach enhances warehouse efficiency, reduces lead times, and enhances customer satisfaction. We can provide the best warehousing experience to increase your productivity.

Avoiding Common Mistakes When Choosing a Warehousing Solution

Businesses seeking to boost productivity and simplify logistics must choose the appropriate warehouse solution. Ultimately, when making this crucial choice, it is crucial to avoid frequent blunders. Many choose a warehouse solution based only on price, which is a common error. However, it is critical to also assess the provider’s capabilities, experience, and reputation. Choosing a strategically located storage facility is crucial for logistics efficiency. It can reduce transportation costs, improve supply chain performance, and minimize lead times.

It is important to consider how scalable and adaptable a warehousing solution is. As businesses expand, their warehousing requirements may change. Working with a provider that can adapt to growth and changing needs is essential for long-term success. By choosing One Union Solutions, you can avoid these mistakes.

Maximizing Efficiency: Why Our Warehousing Solution is the Right Choice

If you are seeking a reliable shipping and warehouse partner in Peru, Warehousing Services by One Union Solutions is here for you. Warehousing Services in Peru are a dependable choice for shipping and warehouse requirements. The company provides various services, such as storage, allocation, and transport solutions. We cater to the medical, automotive, tech, and aviation industries. One Union Solutions in Peru delivers trustworthy solutions. With top-notch facilities, a skilled team, and a customer-centric approach, we are the ideal option for enhancing logistics and efficiency.

Our warehousing services in Peru offer secure storage facilities and flexible space solutions for both long-term and short-term needs. We provide inventory management and value-added services to enhance warehouse operations. Our experts can handle transportation, labeling, packaging, order picking, and quality assurance with precision and accuracy. Contact us today to discuss your warehousing requirements and discover how we can help your business succeed.