Malaysian Warehousing Facilities

A varied assortment of warehouses in Malaysia can help a variety of sectors. Malaysia is a key location for your warehousing needs, whether you need distribution centers, bonded warehouses for customs clearance, temperature-controlled storage for perishable goods, or other specialized facilities. Its proximity to key Southeast Asian maritime routes and well-connected ports make it an appealing option for enterprises looking for efficient storage and distribution solutions.

Malaysian businesses can also take advantage of a plethora of third-party logistics firms specializing in various storage and transit solutions. These service providers handle critical operations like inventory management, order processing, packing, and shipping, allowing your organization to concentrate on its core skills. Malaysia has developed as a prominent center for related services, delivering faster turnaround times and greater reliability through direct order fulfillment from warehouses as e-commerce continues to thrive.

Malaysian warehouses prioritize safety by implementing a variety of protocols such as CCTV surveillance, access control systems, fire alarms, and 24-hour security guards. These facilities closely comply with safety, health, and environmental requirements, ensuring that all items are stored and handled responsibly. Many Malaysian warehouses also implement environmentally friendly practices such as energy-efficient lighting, recycling programmes, and green building designs.

Key Factors for Effective Warehousing

To maintain seamless operations, effective warehouse management necessitates certain qualities and practices. It is critical to streamline warehouse procedures, from receiving through picking and shipping, in order to maintain high productivity and avoid delays. Stocking and picking operations are facilitated by well-defined lanes on the warehouse floor, while precision and accuracy in shipping processes are equally vital.

Employee training is critical in warehouse operations. Employees should be familiar with warehouse layout, processes, and safety protocols. Proper training prevents inefficiencies and ensures that all personnel follow best practices. Here are some crucial factors:

Standard Operating Procedures: Well-defined standard operating procedures are the core of any successful warehouse. These policies ensure that all personnel adhere to defined norms in order to keep operations running properly. Maintaining efficiency in the long run requires consistency.

Streamlined procedures: To avoid delays and maximize efficiency, warehousing procedures such as receiving, picking, and shipping must be streamlined. Stocking and picking are facilitated by clear and easily accessible lanes on the warehouse floor, but shipping procedures must prioritize precision and accuracy.

Staff Efficiency: The efficiency of your warehouse staff is critical to the overall performance of your storage operations. Employees must be well trained and conversant with the layout, culture, and processes of the warehouse. To maintain excellent standards, both veteran warehouse employees and new workers require ongoing training.

Improving Warehouse Safety: Warehouse safety entails more than simply closing the doors at the end of the day. In today’s digital age, protecting sensitive information is equally crucial. Cybersecurity measures must be implemented to protect computers that carry crucial stock and shipment data. Because trust and reputation are at stake, information security is critical.

Utilizing Technology: A well-managed warehouse uses cutting-edge tools to increase efficiency and reduce waste. While not every warehouse requires full automation or customized data monitoring solutions, sticking to obsolete tools can result in production constraints. Keeping up with technology improvements in labor-saving devices such as powerlifters and electric automobiles allows a warehouse to remain competitive.

Enhancing Safety and Security:- Security extends beyond simply closing the doors at the end of the day. Warehouses in Malaysia must protect their computer systems, which include important inventory and shipment data, in addition to physical security measures. Protecting customer trust and private information is critical, hence strong cybersecurity measures are required.

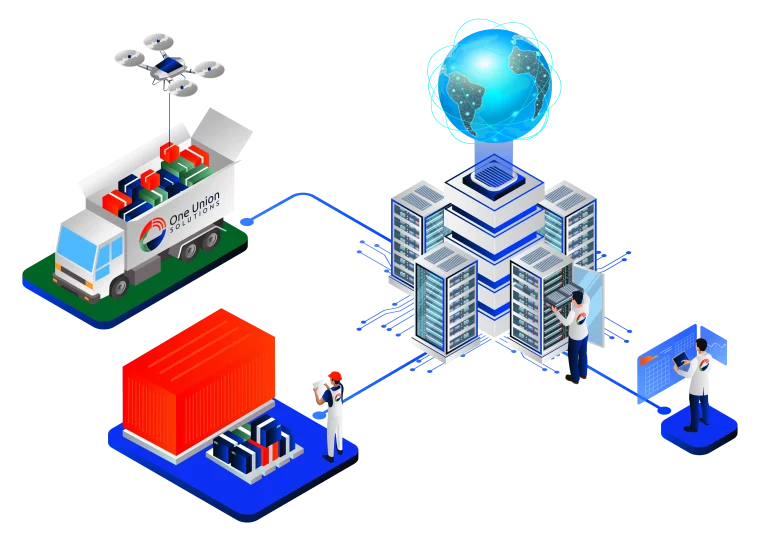

Utilizing Technology in Supply Chains

Malaysian warehouses that are successful use cutting-edge technology to increase productivity and reduce waste. While full automation may not be required for every warehouse, keeping up with technological improvements such as automated material handling equipment and electric cars keeps warehouses competitive.

Advantages of Utilizing Warehouse Services for Your Business in Malaysia

- Convenient Location: Centralised warehousing in Malaysia enhances inventory control and assures timely delivery, resulting in cost savings and increased operational efficiency.

- Possibilities for Development: When unforeseen expansion opportunities arise, you will not be bound by physical storage restrictions. Malaysian warehouse systems are adaptive and can meet your changing needs.

- Distribution Focus: Contrary to popular belief, outsourcing distribution and storage needs might result in cost savings. Warehouses frequently consolidate commodities, resulting in lower transportation costs and the elimination of the need for an in-house shipping department or packing materials.

Types of Warehouses in Malaysia

Private Warehouses: These are warehouses that are exclusively owned and operated by one company. Private warehouses give you complete control over security, inventory management, and storage methods.

Public Warehouses: The general public can use public storage facilities. Companies can rent storage space in a public warehouse. These facilities provide shared storage space and services, making them an economical choice for enterprises with variable storage requirements.

Specialized Warehouses: Some Malaysian warehouses provide specialized services such as perishable products cold storage, beauty product distribution, and comprehensive product distribution. These facilities meet the needs of specific industries.