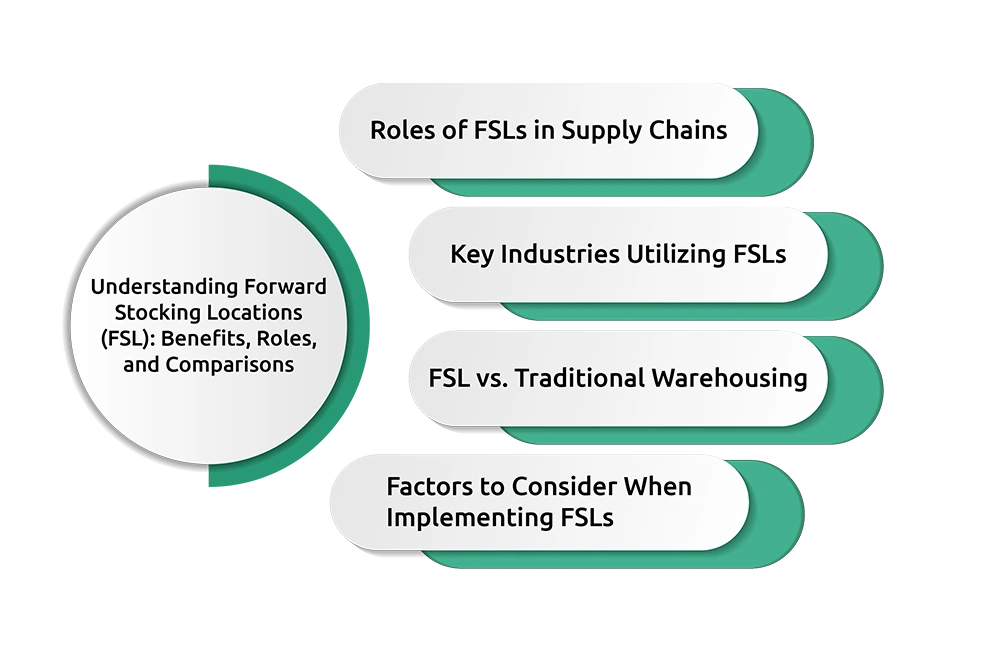

Overview of Forward Stocking Locations (FSL):

A Forward Stocking Location (FSL) is a decisively positioned storeroom that permits organizations to keep their popular stock near clients or key functional center points. These areas assume an essential part in further developing store network productivity by decreasing conveyance times and guaranteeing quick access to crucial items. Especially in enterprises where time is basic, like IT hardware, clinical gadgets, and aeronautics, FSLs empower organizations to answer quickly to client needs and limit disturbances.

By situating stock in key geographic areas, organizations can improve administration levels, lower transportation costs, and smooth out the coordinated factors process. Whether it’s extra parts for upkeep or hardware expected for critical activities, FSLs are an essential tool for organizations meaning to stay serious in the present speedy market.

Importance of Efficient Inventory Management in Global Supply Chains:

In an increasingly globalized marketplace, organizations face the test of exploring complex import and commodity guidelines while guaranteeing their items arrive at clients productively. This is where administrations like Importer of Record (IOR), Exporter of Record (EOR), and DDP (Delivered Duty Paid) delivery services become vital. IOR and EOR administrations work with consistency with nearby regulations, guaranteeing smooth traditions and freedom and decreasing the dangers related to worldwide exchange.

By integrating FSLs with IOR and EOR services, businesses can not only optimize their inventory management but also ensure that goods are moved seamlessly across borders. DDP delivery services further improve this interaction by permitting organizations to deal with all delivery-related obligations, expenses, and customs costs forthright, giving clients a problem-free encounter. Together, these administrations engage worldwide stockpile chains to work all the more productively, decrease postponements, and keep costs unsurprising.

The Role of FSL in International Logistics

Optimizing Inventory with FSL: Forward Stocking Locations (FSLs) play an urgent part in enhancing stock administration for organizations working in global business sectors.. By positioning stock closer to critical demand points, companies can reduce lead times and improve response times for customers. In industries like IT/Data Centers, Medical Equipment, Aviation, and the Automobile sector, where downtime can lead to significant financial losses or operational delays, FSLs provide an essential buffer by ensuring fast access to spare parts, replacement components, and essential products.

How FSLs Complement Importer of Record (IOR) Services: The integration of Forward Stocking Locations with Importer of Record (IOR) services is a strong blend for organizations overseeing worldwide stock. IOR administrations guarantee that products are imported in full consistence with the nearby traditions guidelines, including adherence to assessments, obligations, and import limitations. At the point when an FSL is matched with IOR administrations, organizations can smooth out the importation interaction, permitting stock to arrive at neighborhood showcases rapidly and effectively.

Integration of Exporter of Record (EOR) with FSL: Forward Stocking Locations also complement Exporter of Record (EOR) services, making an effective structure for worldwide shipments. EOR administrations deal with the lawful obligation regarding sending out merchandise starting with one country and then onto the next, taking care of consistency with trade guidelines, and it is accurately handled to guarantee all documentation. This cooperative energy with FSLs guarantees that merchandise can be immediately dispatched to worldwide objections while remaining agreeable with trade regulations.

Benefits of Forward Stocking Locations (FSL)

Improved Delivery Times:

One of the essential advantages of Forward Loading Areas (FSLs) is their capacity to definitely decrease transporting distances and conveyance times. By situating stock in essential areas near clients or key functional center points, organizations can answer orders a lot quicker than if they depended on concentrated distribution centers situated a long way from their end clients

Cost Reduction:

FSLs are a cost-effective solution for managing inventory and logistics. By decisively putting FSLs in locales with exclusive requirements, organizations can diminish transportation costs fundamentally. Rather than delivering items over significant distances, organizations can make more limited, more continuous shipments from nearby FSLs, eliminating transporting costs, particularly for earnest or sped-up orders.

Enhanced Customer Support:

Having stock nearer to clients permits organizations to offer improved help, particularly while managing pressing or time-delicate orders. FSLs empower fast reaction times, guaranteeing that items are accessible when clients need them most. This is especially significant in ventures like clinical gear and IT administrations, where hardware disappointment or supply deficiencies can have basic results.

Industry Use Cases for FSL

IT and Data Center Equipment:

In the fast-paced IT and data center industries, uninterrupted operations are paramount. Forward Stocking Locations (FSLs) give an essential advantage by keeping principal gear, similar to servers, sorting out parts, and limiting contraptions, near client districts. With FSLs unequivocally arranged in key regions, IT expert centers can ensure speedy permission to urgent parts, restricting leisure time in the event of gear frustration or system redesigns.

Medical Equipment Sector:

The medical care industry depends on the opportune accessibility of basic clinical supplies and gear to guarantee patient consideration is rarely compromised. FSLs are crucial for clinical benefits providers as they consider the fast transport of key things like characteristic devices, cautious instruments, and clinical consumables. By arranging stock close to centers and clinical consideration workplaces, FSLs can answer quickly to sincere requests, diminishing lead times and ensuring that life-saving equipment is reliably reachable.

Automobile Sector:

The automotiveindustry relies upon the accessibility of extra parts to keep vehicles out and about and guarantee consumer loyalty. FSLs empower car organizations to stock crucial parts, for example, engine parts, tires, and electronic systems, near showrooms and fix focus. This limited methodology considers quicker fixes and upkeep, decreasing vehicle margin time and further developing client care.

Aviation Industry:

The aviation industry is intensely dependent on accuracy and timing, particularly concerning the accessibility of extra parts for airplane support. FSLs assume a fundamental part in guaranteeing that carriers and support suppliers approach basic parts like motors, landing stuff, flying, and other fundamental hardware. With FSLs decisively positioned close to air terminals and aeronautics centers, organizations can rapidly get the parts they need to perform routine upkeep or pressing fixes.

Conclusion

As worldwide stockpile chains become more complicated and organizations progressively request quicker, more dependable admittance to stock, Forward Stocking Locations (FSLs) will keep on assuming an urgent part. The mix of FSLs with Importer of Record (IOR), Exporter of Record (EOR), and DDP delivery services offers organizations a complete answer for smoothing out worldwide coordinated operations. This incorporation guarantees quicker conveyance times as well as ensures consistency with administrative prerequisites, limiting postponements and dangers.

Looking forward, FSLs will be much more fundamental as ventures like IT, clinical gear, aeronautics, and automotive sectors keep on extending their worldwide reach. Organizations should keep an upper hand by situating stock near key business sectors and clients, considering the fast reactions to requests. As organizations embrace computerized change and push toward more nimble, client-driven models, FSLs will stay a foundation of a productive inventory network for the executives.

FAQs

What is a Forward Stocking Location (FSL)?

A Forward Stocking Location (FSL) is a decisively positioned distribution center or storage space used to keep fundamental stock near popularity regions.

How do Forward Stocking Locations benefit global supply chains?

FSLs benefit worldwide stock chains by decreasing the distance and time expected for conveyances, limiting transportation costs, and guaranteeing that basic stock is promptly accessible in locales where there is popularity.

How do FSLs complement Importer of Record (IOR) and Exporter of Record (EOR) services?

FSLs work alongside IOR and EOR services by streamlining the process of importing and exporting goods. IOR services ensure that goods are imported in compliance with local regulations, while EOR services manage outbound shipments.

What industries benefit the most from using Forward Stocking Locations?

Enterprises that depend on convenient accessibility of basic parts and hardware, like IT/Server centers, clinical gear, aeronautics, and the automotive sector, benefit the most from utilizing FSLs. These ventures need quick, solid admittance to save parts and parts to limit functional free time, and address client issues.

How do FSLs support Data Center Solutions?

FSLs support Data Center Solutions by putting away fundamental equipment parts, for example, servers and systems administration gear, and closing the data center. This nearness considers quick substitution of flawed or obsolete hardware, limiting free time and guaranteeing continuous tasks for organizations depending on these offices.

Did You Know?

The Port of Shanghai, one of the world’s most active ports, handles more than 43 million TEUs (twenty-foot comparable units) every year, making it a critical center point for worldwide inventory chains, and a vital area for decisively setting Forward Loading Areas to improve imports and products.